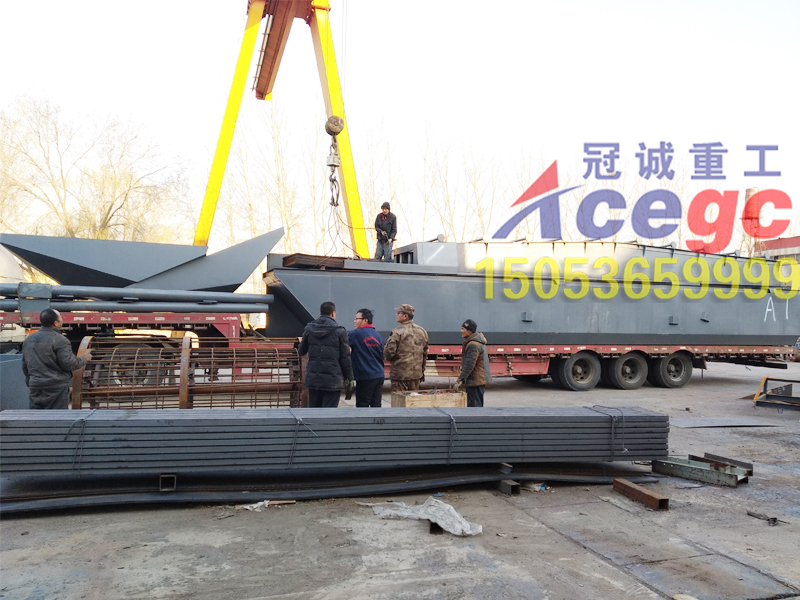

Automatic washing gold mining machine

Introduction

Automatic washing and mining machine is also called belt sluice, it belongs to gravity concentration equipment. The conveyor belt is made by cycloconveyor belt in the process of sulfidem, there is grid type figure on the belt surface, these grids with strip are used for storage of heavy mineral particles. The density stratification is under the combined action of impulsive force, gravity of mineral particles and friction force of tank bottom, the heavy mineral particles deposit in the grids, becomes into high-grad ore, the light mineral particles are washed away by water and becomes into tailing, which could reach the purpose of Separation.Noticed Factor

1. Belt Surface Operating Speed: If other conditions are same, if belt surface operating speed is higher, the sand gold concentration ratio is lower, the recovery rate will be more higher. Otherwise is opposite. In general, 3.5-4m/min is standard.

2. Slope Grade of Belt Width: If other conditions are same, if the slope grade is bigger, the mineral particles which on the belt surface will be not balanced and come into part race, which will make the recovery rate be lower, it is not good for separation, meanwhile, the slope grade exceeds the certain limit, the mineral particles running speed on the belt surface will be lower. As normal, the degrees of sand gold is in the range of 13-15.

3.Feeding Capacity: If other conditions are same, the feeding capacity is bigger, the concentration ratio of sand gold will be lower, recovery rate will be lower, too, thus the bigger feeding capacity makes the belt surface flow rate being very big, all kinds of minerals will be washed away directly, especially for the sand gold, the feeding capacity should be done as per the sluice width and length.

4. Feeding Concentration: The slurry flow rate will be reduced along with bigger feeding concentration, the hierarchy of mineral particles will not be clear,the recovery rate will be reduced. If the feeding concentration is too small, the belt surface flow rate will be faster, the recovery rate will be lower. The test result proved that feeding concentrate in the range of 30%-40% is better.

5. Feedwater Quantity: Gold washing and mining machine should fill in enough water for improving the concentration ratio. But if other conditions are same, if feedwater is too big, the gold on the grids will be washed away. But if the concentration ratio reduces, it will cause a certain burden.

Detail parameter

|

Size(m) |

Capacity(t/h) |

Motor Power(kw) |

Recovery Rate |

Material |

|

4x1.4 |

100-120 |

5.5 |

95% |

polyester circular belt |

Previous content:River gold dredging boat

Next page:Portable trommel screen car&horizontal centrifuge concentrator plant

产品分类

/PRODUCTS- Gold Mining Machine

- Crusher equipment

- Dredger

- Sand Processing Machinery

- SOLUTION

- Gravity Beneficiation

相关新闻

/NEWS- Mobile gold car gold mining machine on manufactruing

- Fixed gold mining machine 300 m3/hour alluvial gold mining

- The gold mining equipment mobile concentrator car send to Indonesia

- Affect reason rock gold mine fully crushing&grinding

- The gold mine and separating in Democratic republic of Congo

- Work capacity 100-150ton/hour vibrating gold mining machine

- Stationary type vibrating screen gold mining machine

- Desert gold mining machine dry gold separating plant

- Container Loading:Mobile gold mining machine send

- Mobile gold trommel concentrator mining machine on land

联系我们

/CONTACTQingzhou Guancheng Heavy Industrial Machinery Co.,Ltd.

+86 536 3593111

地址:Dongjiande Village, Huanglou Street Office, Qingzhou, Shandong, China (Mainland)

电话:+86 536 3593111

传真:+86 536 3593111

手机:+86 15653473333,15053659999

Email:1592999333@qq.com